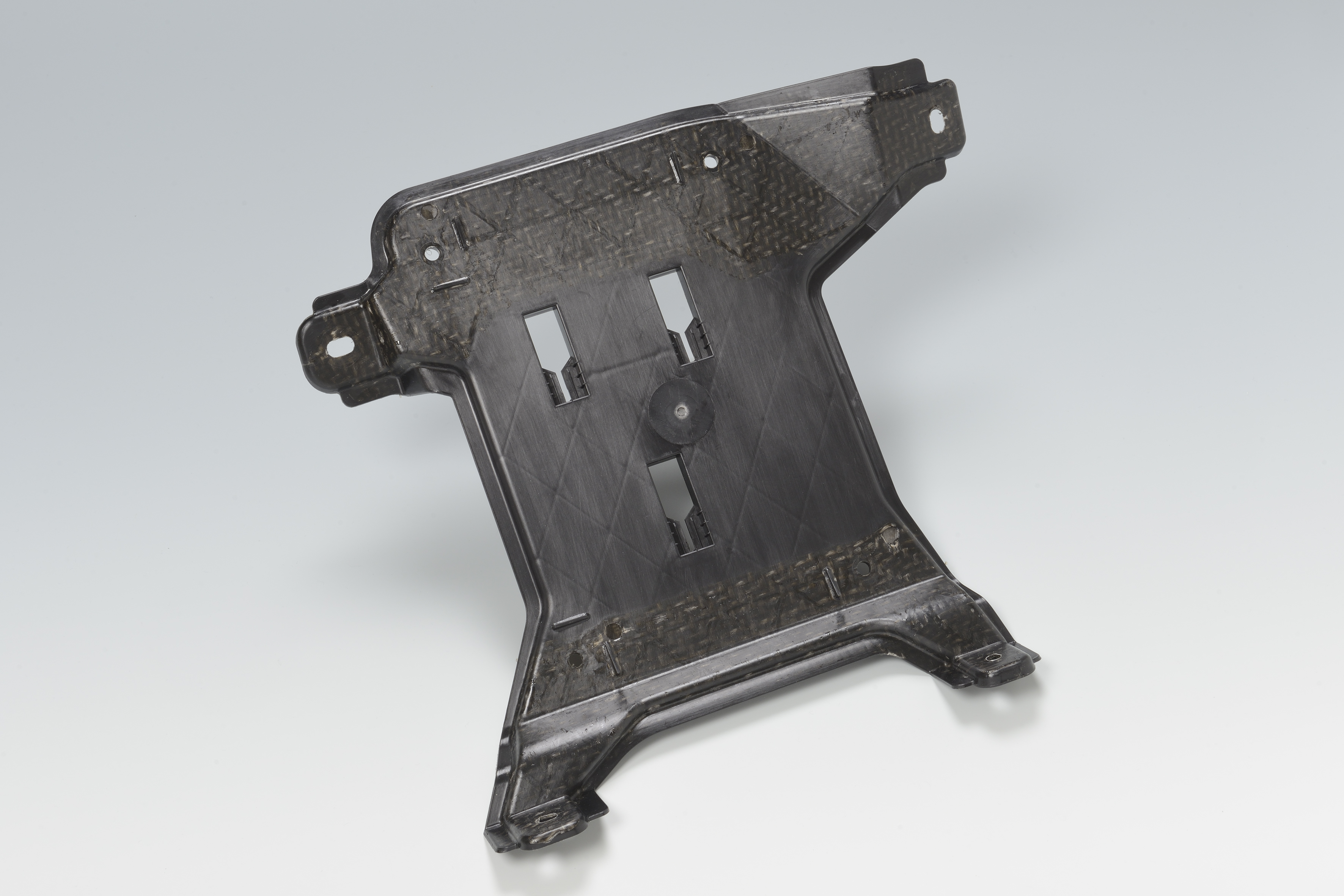

Infotainment Carrier | Audi A6

details of use case

An infotainment carrier of hybrid design, made from a continuous fiber-reinforced polyamide composite and a polyamide 6 overmolding material, is being used for the first time in the Audi A6.

| advantages | Reduces weight by nearly 50 percent compared to its steel counterpart due to hybrid design |

| material | Insert: Tepex dynalite 102-RG600(2)/47% (organic sheet with continuous fiber reinforcement with PA 6 matrix)

Compound: Polyamide 6 Durethan BKV 30 EF H2.0 |

| process | One-shot process

Holes for the screw connections are formed by mandrels inside the injection mold when it is closed, no separate process step required |

| development status | Mass production

Cycle times: < 50 seconds |

| development partners | Audi, LANXESS, KraussMaffei Technologies GmbH, KRELUS AG, Christian Karl Siebenwurst GmbH & Co. KG Modellbau und Formenbau, Reinert Kunststofftechnik GmbH und Co. KG |

further information

Access to full article: Lanxess Press Releases. For more use cases please enter Lanxess Press Releases.

your contact

Schirin Walter

Bond-Laminates GmbH

Am Patbergschen Dorn 11

59929 Brilon, Germany

schirin-walter@bond-laminates.de

+49 2961 96628 509

Lanxess Deutschland GmbH

Kennedyplatz 1

50569 Köln

Germany

company profile

our use cases