Airbag Housing

Short Cycle Times <60s through Injection Molding Process

Thermoplastic composites are becoming increasingly popular in highly cost-driven markets. Thermoplastic composites consist of a thermoplastic matrix combined with various reinforcing materials such as short, long or continuous glass or carbon fibers. Processes for the production of thermoplastic composites include injection molding, compression molding, tape placement, winding and thermoforming.

Benefits of thermoplastic composites are:

Due to the usage of continuous fiber-reinforced inlays, mechanical properties can be increased significantly in comparison with purely thermoplastic compounds. The ductility of the thermoplastic resin leads to high impact resistance and damage tolerance. Hybrid thermoplastic composite parts enable high functional integration and thus a high potential for cost efficient production. The functional integration can be achieved by injection or compression molding of short fiber reinforced compounds or welding.

The processing of thermoplastic composites can reach cycle times of one minute and below – defined by the cooling of the thermoplastic matrix – and therefore allows for high-volume production. Flexible manufacturing cells based on state-of-the-art injection molding machines or presses are used for production. Therefore, the same equipment can be used for various parts.

Thermoplastic composites require uncomplicated production processes as no adhesive resins or evaporations are involved. Furthermore, starting and stopping of processes is possible. This leads – in combination with quality-controlled semi-finished products – to a good reproducibility of the thermoplastic composite processes allowing for mass production of thermoplastic composite parts such as car body front ends or seat structures.

Due to the re-meltable thermoplastic matrix, thermoplastic materials can be re-used, e.g. as short fiber reinforced plastics and thus improve the life cycle analysis significantly.

Short Cycle Times <60s through Injection Molding Process

Manufacturing premium bicycle components

First Hybrid-Molded Rear Bumper Beam

Lightweight material with high mechanics and weather resistance

High-Level Energy Absorbtion

Reduces Weight by nearly 50%

A multi-material hybrid seat structure

High impact resistance and cost-efficient mass production

Resistant to Low Temperatures

Maezio® composites in seatbacks

Construction of an ultra-thin yet robust table

Weight saving & long term stability

Improve the aerodynamic performance

Additives | Technical Service | Formulation Development

Design and Simulation | Process Optimization and Consulting

Double Belt Presses | Components for Steel Belt Machines | Technical Support | R&D Center for Prototyping

Design and Simulation | Polymer Resins and Additives | Fibers | Compounds | Unidirectional Tapes | Injection Molding

Production Systems | Tooling | Finishing and Assembly | Automation | Prototyping

Production Systems | Automation | Individual Production Solutions | Prototyping

Machinery and Tooling | Production | Diode lasers and optics for CFRP and polymer processing | Laser systems for thermal treatement

Glass Fibers

Concept Design | Process & Structural Simulation | Materials | Process Optimization & Consulting

Design | Manufacturing

Process Design and Modelling | Process Simulation and Benchmarks | Process Costing | Consulting

Production Systems | Tooling | Automation

Equipment for Tape Placement & Winding | Fully automated production units | Prototyping | Product Development

Design and Simulation | Polymer Resins and Additives | Short Fiber Compounds | Laminates and Sheets

Design | Prototyping | Manufacturing

Specialty Additives | Compounds | Fillers and Reinforcers | Polymer Resins

Complete production equipment | Short overall process time | Forming of semi finished products

Reinforcement materials | Yarns | Fabrics | Unidirectional Tapes

Honeycomb sandwich cores | Sandwich panels | Laminates and Sheets | Production Systems | Automation | Individual Production Solutions

Fiberglass | Hybrid Yarns

UD-Tape based on carbon fibers and polypropylene | High performance polymers | Compounding facility

Design and Simulation | Polymer Resins | Unidirectional Tapes

Fibers | Compounds | UD Tapes | Laminates and Sheets | Fabrics | Prototyping | Design Support

Design and Simulation | Polymer Resins | Short Fiber Compounds | Laminates and Sheets

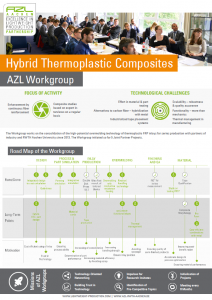

As AZL Partner Companies, we collaborate in workgroups and research and development projects for thermoplastic composites.

Meeting every six months, we work on the continuous improvement of technologies related to “Hybrid Thermoplastic Composites”. As a strong alliance, we define joint activities and generate new business by exchanging pre-competitive information between all relevant players along the value chain. The close connection to the broad research centers of the AZL network facilitates direct initialization of development projects.

Meeting every six months, we work on the continuous improvement of technologies related to “Hybrid Thermoplastic Composites”. As a strong alliance, we define joint activities and generate new business by exchanging pre-competitive information between all relevant players along the value chain. The close connection to the broad research centers of the AZL network facilitates direct initialization of development projects.

Within the Joint Partner Project “Thermoplastic Tapes – Material and Processing Benchmark”, seven AZL Partner Companies addressed the dependencies between tape properties, processability and resulting part properties to extend fundamental knowledge for the initialization of a tape standardization initiative within the consortium. Follow-up projects on the correlation of morphology and mechanical properties of thermoplastic FRP laminates are currently under discussion.

The 18-month Joint Partner Project aims to develop a machine prototype for the feasibility of a novel manufacturing principle, which should be capable of producing tailored composite blanks in high volumes at medium investment cost. The project started in June 2016 with 12 involved partner companies.

The AZL forms an international lightweight network of 9 institutes on the RWTH Aachen Campus and more than 80 companies from 21 countries involved in lightweight production. Learn more…

This business platform provides you with information on thermoplastic composites as well as established suppliers and innovative development partners along the whole value chain. We are a group of leading companies active in thermoplastic composites with a broad experience and product range.

Find more lightweight business partners at our other business platforms.

Besides our individual services, we support you with:

Philipp Fröhlig

Senior Project Manager

+49 241 475735 14

info@lightweight-partners.com